The manufacturing industry is undergoing a significant transformation, often referred to as the Fourth Industrial Revolution or Industry 4.0. This revolution is driven by the adoption of new technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics. None of which is possible without data from manufacturing companies and analytics solutions to process and generate actionable insights from this data.

Today, leveraging data is critical for driving innovation, improving efficiency, and maintaining profitability. But what data is collected across entire manufacturing supply chains? What is it used for? And, how can this data be used without compromising trade secrets, data privacy, or operational integrity?

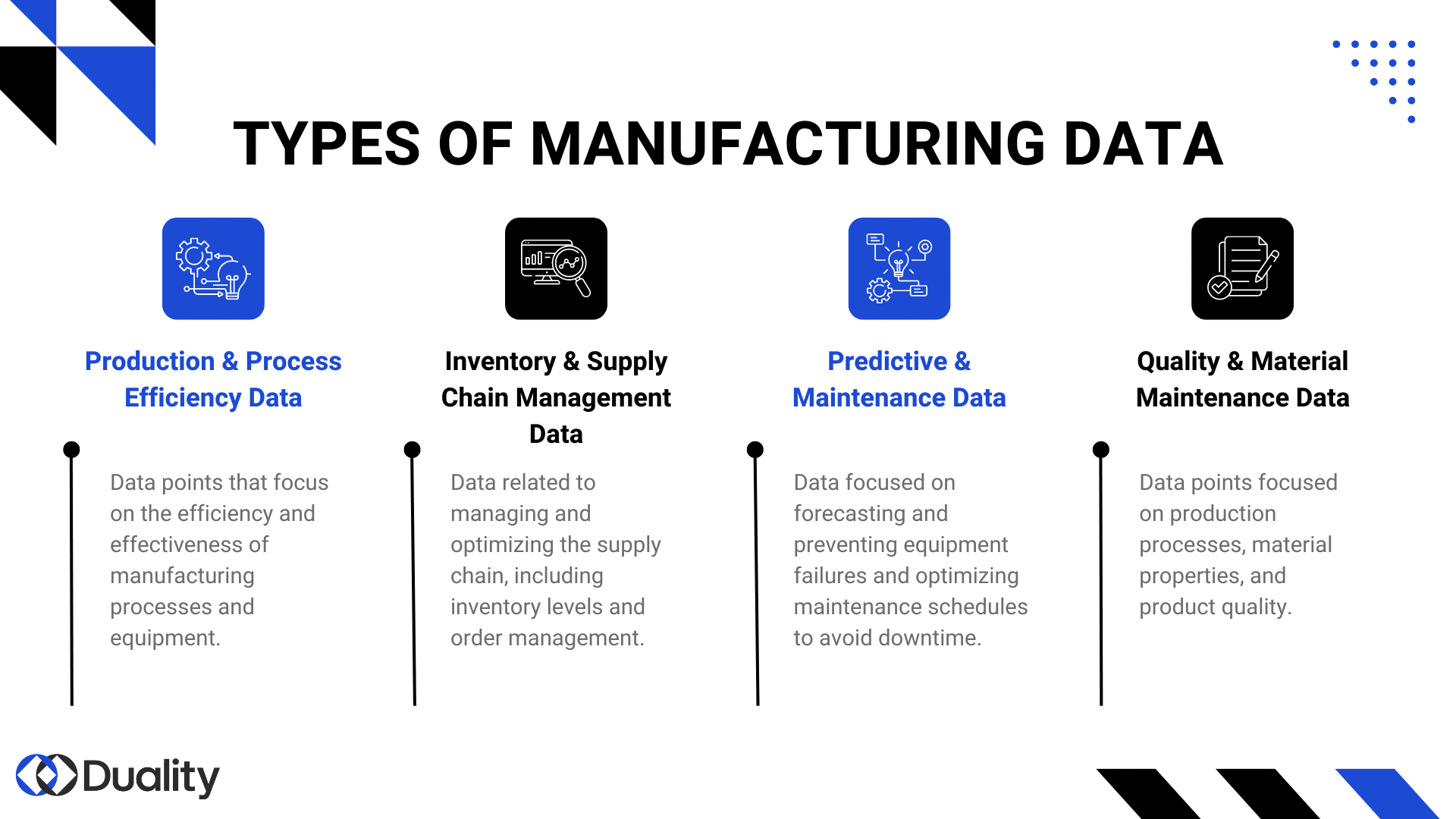

The Types of Manufacturing Data

Let’s start at the beginning. What types of data are collected in the manufacturing industry and why are they valuable?

Production and process efficiency data

Data points that focus on the efficiency and effectiveness of manufacturing processes and equipment.

By analyzing production line data, cycle time, capacity utilization, and overall equipment effectiveness (OEE), manufacturers can identify bottlenecks, streamline workflows, and optimize production schedules. Monitoring production rates and downtime helps improve productivity and reduce operational costs by ensuring that equipment and processes are functioning at peak efficiency.

Inventory and supply chain management data

Data related to managing and optimizing the supply chain, including inventory levels and order management.

Accurate inventory data minimizes stockouts and excess inventory, optimizing inventory levels and improving cash flow. Additionally, enhanced traceability and better decision-making in logistics and supplier management lead to reduced costs and increased efficiency in the supply chain.

Predictive and maintenance data

Data focused on forecasting and preventing equipment failures and optimizing maintenance schedules to avoid downtime.

Predictive maintenance, which uses historical data and advanced analytics to forecast potential equipment failures, allows for proactive maintenance and prevents costly breakdowns. Ensuring smooth equipment operation enhances overall productivity and reduces interruptions, contributing to operational continuity desired by both vendors and customers.

Quality and material management data

Data points focused on production processes, material properties, and product quality.

Quality control is maintained by monitoring production processes and material properties, which helps in reducing waste and ensuring consistent product standards. Furthermore, understanding material usage and costs enables manufacturers to optimize material procurement and usage, thus lowering costs and improving the quality of the final product.

These types of data, when effectively collected and analyzed, allow for optimized manufacturing operations, improve product quality which results in significant cost savings.

What Are The Options for Utilizing This Data?

Most manufacturing companies are not maximizing the potential of their data combined with data throughout their supply chains because they lack the solutions and data safety guarantees to access and fully leverage it. So, what should your data strategy be? Here are two primary options:

Adopt an AI Model

Adopting AI models can provide significant insights and drive efficiency, but it comes with several challenges:

- Not Enough Data: Many manufacturers may not have sufficient data to train robust AI models. This limits the effectiveness of AI in making accurate predictions and driving improvements.

- Data Protection Concerns: Partnered organizations in a manufacturing supply chain may hesitate to or reject sharing unprotected data given the significant risks of doing so, including breaches of sensitive information and intellectual property theft. This makes it crucial to have secure data handling and collaboration solutions.

- AI Developer Constraints: When customers are unable to share their data, AI developers are still reluctant to share their models due to concerns about protections for global data sets and intellectual property as found in the weights and features of their models. This creates a barrier for manufacturers seeking to leverage AI without compromising their proprietary information.

Sell Your Data to Model Developers

Selling data to AI model developers can turn robust data collection from a cost center into a revenue generator. However, this also comes with its own set of challenges:

- IT & Operational Overhead: Traditionally, teams would set up infrastructure dedicated to a data-sharing revenue model to ensure proper data cleaning, preparation, access controls, governance, etc. The capital and operational expenses can be prohibitive.

- Data Privacy and Security: Ensuring that the data being sold is anonymized and protected to prevent misuse or breaches is paramount. Manufacturers need to implement strong data governance policies to safeguard their information.

- Intellectual Property Protection: Manufacturers must ensure that their intellectual property is protected when sharing data. This involves legal agreements and technological measures to prevent unauthorized use or replication of proprietary data.

Using Data in Manufacturing with Secure Data Collaboration

Secure data collaboration solves the major challenges of leveraging your manufacturing data.

#1 Testing and Adopting AI Models Securely

Secure AI and data collaboration enables secure testing and adoption of AI models by providing a platform that ensures data privacy. Manufacturers can run 3rd party AI models on their data without exposing the underlying sensitive information and while ensuring protection of the model itself. This secure environment enables organizations to quickly and securely compare competing models on their real data, providing confidence in quick decision-making.

#2 Transforming Data into a Revenue Generator

A secure data collaboration platform facilitates the monetization of data by enabling manufacturers to securely share or sell their data to AI developers. The privacy and security by design solution eliminates and minimizes the traditional IT and operational expenses of such an operation. This transformation of data from a cost center to a revenue generator is achieved through secure data collaboration, ensuring that data privacy and intellectual property are protected while creating new business opportunities.

#3 Leveraging Additional Data Integration While Protecting IP

Secure data collaboration allows manufacturers to integrate external data sources securely with technical guarantees of data protection and governance. This capability enhances the AI models they have invested in by providing more comprehensive data inputs from their entire supply chain, leading to better insights and ROI on AI investments. At the same time, it ensures that both the model’s intellectual property and the data owners’ privacy are rigorously protected, fostering a secure and collaborative data environment all data owners can trust.

Conclusion

Leveraging data is vital for innovation, efficiency, and profitability for the manufacturing industry, but doing so securely is a significant challenge. Duality Technologies offers a secure data collaboration platform that enables manufacturers to adopt AI models, monetize data, and integrate additional data sources while protecting sensitive information and intellectual property. By utilizing data solutions like Duality, manufacturers can fully harness their data’s potential, drive innovation, improve processes, and maintain a competitive edge in the evolving digital landscape.

Sources